BALL MILLS Ball mill optimisation - Holzinger Consulting

Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with

Grinding in Ball Mills: Modeling and Process Control - Sciendo

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical

(PDF) Design and Fabrication of Mini Ball Mill (edited)

2016年4月25日 PDF This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into fine powder and... Find, read and cite all

(PDF) ball mill Sheetanshu Pandey - Academia

SUBJECT: SAG MILL + BALL MILL CIRCUIT SIZING Summary: Most large tonnage mineral processing facilities consist of a primary SAG milling and secondary ball milling

Ball Milling - umb

A ball mill is a type of grinder used to grind materials into extremely fine powder. Major parameters for ball milling. Temperature. and Number of the balls. Nature of the balls.

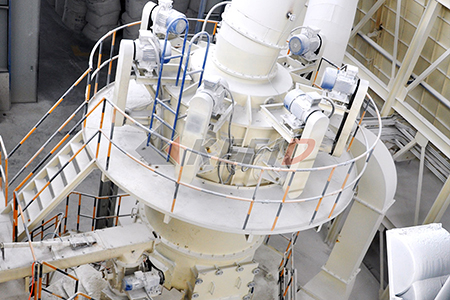

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

Introduction. Ball Mill. Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. Dry Ball Mill: I. It is mainly

University of Liège - uliege

Ball mills, i.e. rotating cylindrical drums filled with a feed material and metal balls, also known as the charge, are a major category of grinding devices in mineral processing and

Verder Scientific Customer Magazine Issue 44 BALL MILLS

The RETSCH ball mill range is the most extensive offering in the world, providing a high degree of flexibility. The portfolio comprises mixer mills, planetary ball mills, high

(PDF) Energy Efficient Ball Mill Circuit – Equipment

2013年7月15日 PDF The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and ...

Power MILL 2017 Training Data And PDF - Archive

2018年5月3日 Power MILL 2017 Training Data And PDF by Eng/ Ahmed Hany. Publication date 2018-05-03 Topics cad cam cnc Language English Item Size 134151190. powermill learning ملفات التعليم الخاصة ببرنامج بورميل الصادرة من شركة اوتودسك لنسخة 2017 ...

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. Ⅰ. It is mainly used in refractory, fertilizer, cement and glass industries; Ⅱ. The dry ball mill has strict requirements on the

Ball Mill: Standard Operating Procedure PDF - Scribd

BALL_MILL_STANDARD_OPERATING_PROCEDURE_-.doc - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. The document provides standard operating procedures for a ball mill. It lists 18 steps for operating the ball mill, including connecting power, loading materials and grinding media, starting and stopping

BALL MILLS Ball mill optimisation - Holzinger Consulting

process. Together with ball charge composition, both tools – liners and media – can be optimally adjusted for the application. They can then fulfil the Figure 2: ball mill tools and comminution process Figure 1: ball mill communition process chain Ball charge management grinding Ventilation and cooling Operation and control

Ball-Mill-Manual.pdf - PDFCOFFEE.COM

Ball-Mill-Manual.pdf; Ball-Mill-Manual.pdf. Author / Uploaded; Andrews Osei; P.O. Box 9411 Edenglen 1613 Tel: (+27) 11 454 4177 Fax: ... New Project Management Development cc CK2000/032356/23 VAT4080219712 EL BROCAL 16x22ft, 2800kW BALL MILL MILL SERIAL NUMBER – BAL020 MILL INSTALLATION MANUAL Tel: (+27) 11

Metso Ball Mills Brochure - Metso Corporation - PDF Catalogs ...

Mill lining installation in a ball mill at Atacama Kozan Mining Company, Copiapo, Chile. Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30’ x 41’ . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives.

(PDF) Mill Maintenance in The Age of Industry 4.0 - ResearchGate

2020年7月6日 PDF If we combine Computerized maintenance management system – CMMS CMMS with Industry 4.0’s principle aspects, ... T o achieve industry 4.0 in the mill, three principal as-

FLS - Ball Mill Liners Brochure - DIGITAL PDF Mill (Grinding ...

FLS_Ball Mill Liners Brochure_DIGITAL (1) - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

(PDF) Effect of ball and feed particle size

2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al. [50] using the attainable region technique on a silica ore by dry milling, a three-ball mix of ...

Ball mill PDF - SlideShare

2020年4月1日 Ball mill - Download as a PDF or view online for free. Ball mill - Download as a PDF or view online for free. Submit. Ball mill • 0 likes • 124 views. AI-enhanced description. Ball mill is a grinding device that is

Grinding in Ball Mills: Modeling and Process Control - Sciendo

55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xj.Thus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j. The mechanism of breakage is illustrated in [23] by a diagram shown in Fig. 3.

Grinding in Ball Mills: Modeling and Process Control - Semantic

2012年6月1日 An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented. Abstract The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and

(PDF) Improvement of methods to ensure energy efficiency of ball

2023年8月21日 PDF Mining, metallurgical, ... to ensure stable operation of the ball mill and electric motor at full load. To determine such operating modes and ensure the operation of equipment in them, ...

Exp 4 - Size Reduction Using Ball Mill PDF Metalworking ...

This document describes an experiment to demonstrate a ball mill operation at different speeds and a sieve shaker operation. Coarse stone samples were ground in a ball mill at 20%, 40%, and 60% motor speed for 15 minutes then screened. More stone was ground to 250-600μm size at higher speed, with 0.13g, 0.17g, and 0.24g for 20%, 40%, and 60% respectively. Higher

Ball mill PPT - SlideShare

2015年4月24日 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter

Ball Mill Design Power PDF Mill (Grinding) Iron Ore

Ball Mill Design Power - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides information about grinding mills, including standard sizes and dimensions of mills, descriptions of mill types and components, and methods for estimating mill power requirements. The key details are mill dimensions and specifications for different

BALL MILLS FROM NANO GRINDING TO MECHANOCHEMICAL SYNTHESIS

2019年12月11日 PDF Ball mills are among the most variable and effective tools when it comes to size reduction of hard, ... ball mill required a net grinding time of 30 min with an additional 2.5 hours .